Cantilever compact mill stands are. So for continuous rolling operation this one is the best.

Metals Free Full Text Effect Of Clearances In Mill Stands On Strip End Motion During Finishing Rolling Html

The simple and unique design of the machine lets simple installation with excellent performance in various rolling conditions.

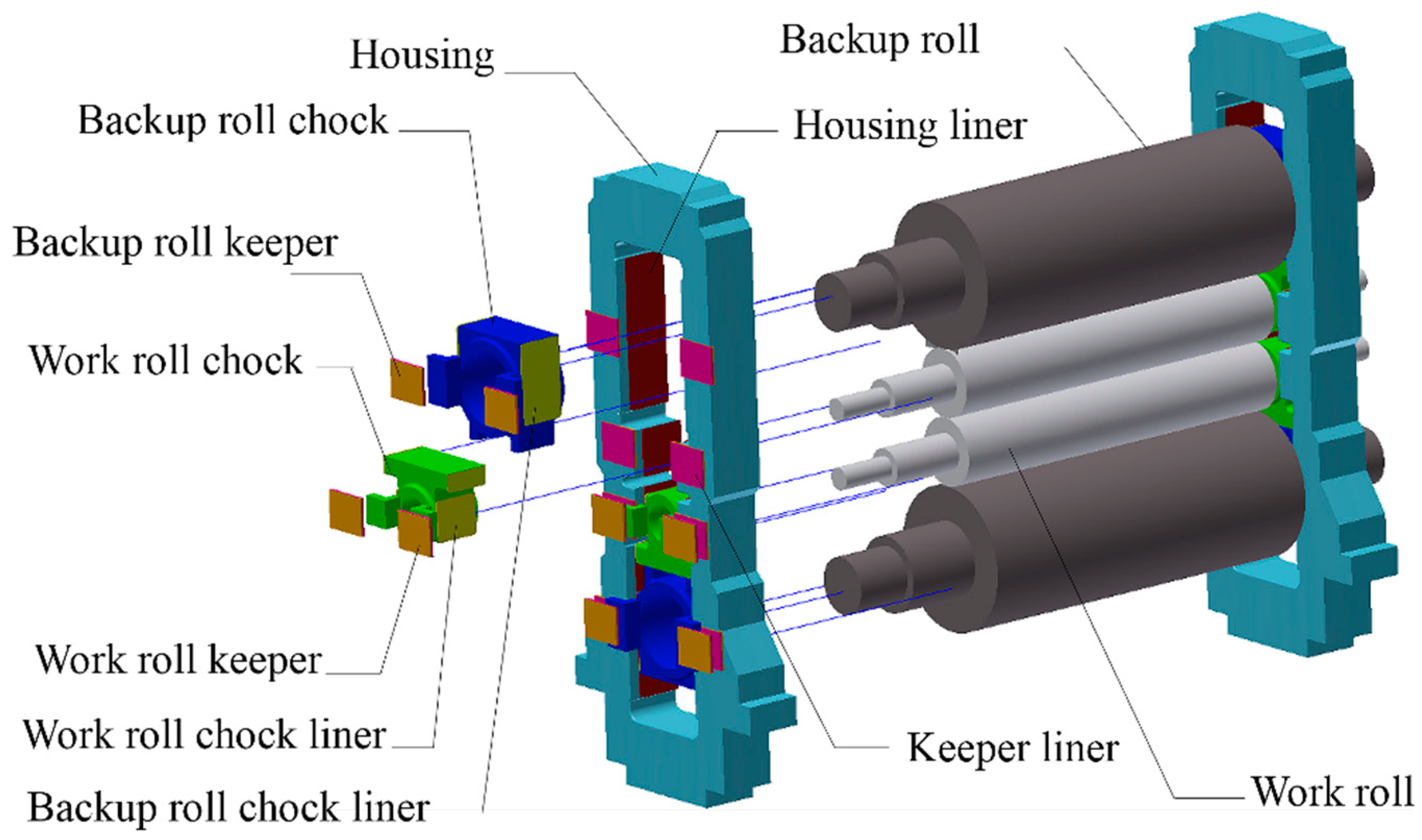

. Designs engineers and manufactures high capacity rollers powered heavy moving systems and custom load moving solutions. Types of Roll Chocks The roll chocks are broadly categorized into 4 types which is shown in fig 3Top Back up Roll Chock 1. The simulation results show that the thickness oscillation can be manipulated with high accuracy by using NARMA-L2 since it can remove the non-linearity of servo system and other disturbances complexities.

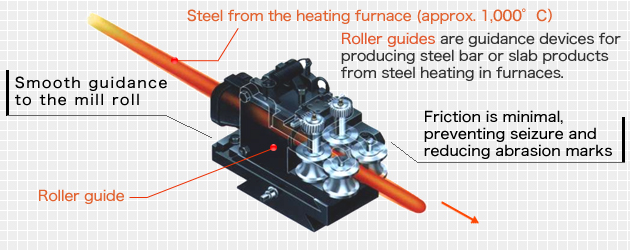

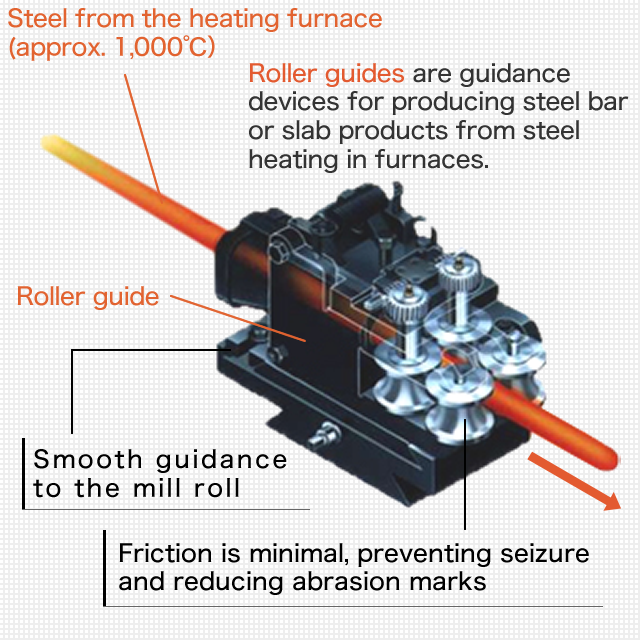

Shri Balaji Roller Guide Box is a major product of hot rolling mill plant and inconsumable items. Read customer reviews find best sellers. Two basic models the force model and the crownshape model dominate major tasks of mill design.

Rolling models serve as theoretical foundation of mill design. Two high rolling mills. Top Work Roll Chock 2.

We provide the best quality of mill guides at a lower price. Bottom Back Up Roll Chock Figure 3 Roll chocks Figure 2 Four high stand of reversing cold mill 4. Ad Developed to CrushGrind Various Materials with an Optimum Result.

1-3TAccording to the actual situation of the customer I customize the design of the small automatic steel bar production line rolling mill plant solution fo. These intervals are not disjoint in general. We manufacture all kinds of mil guides according to clients requirements and deliver them on.

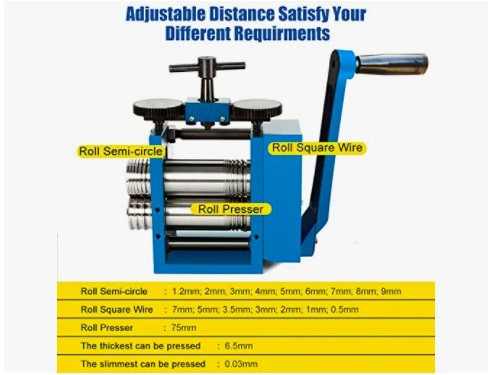

A two-high rolling mill produces a higher quality product than a traditional rolling mill because the rollers are able to apply more pressure to the workpiece. Bottom Work Roll Chock 3. A Simulink and mathematical models have been proposed in this study in order to control the thickness in a rolling mill process.

Hollteck is now recognised as a world leader in the design and manufacturing of Rolling Mill Guides and associated Mill Equipment. A model-based predictive approach is proposed for the strip head motion control during the steel strip infeed in hot rolling finishing mills. Here is the list of hard constraints that must be taken into account by the hot rolling mill.

The housing less stands are normally arranged in horizontal-vertical no twist arrangement which allows no twist rolling which permits larger reduction and smoother rolling as it eliminates twisting oval into round passes as in the conventional oval to round sequence which results in less guide wear and simpler guide design. Two High Rolling Mills. Figure 1 Rolling mill configuration 3.

It contains two heavy rolls fixed one over the other. Each ingot of a particular hardness group has a wear interval within which it can be rolled. Our rolling mill guides box is offered with the good material of rollers for different sections.

The range and quality of Hollteck guide types far exceed that of any other competitor. A two-high rolling mill typically costs less to operate than a traditional rolling mill because the two-high rolling mill uses less energy and requires less maintenance. Ad Browse discover thousands of brands.

Hilman provides easy safe and cost-effective solutions to a wide range of industries. Three high rolling mills. Hollteck has remained at the forefront of casting technology through the use of computerised CAD design and CAM manufacturing.

We offer it along with heavy-duty taper diamond roller. Four high rolling mills. Tendem or Continuous mills.

Following are the 6 different types of rolling mills used in many industries. For moving installing and relocating heavy machinery and large equipment. Forged SS Steel Graded is used to manufacture Mill Guide System.

This is widely used in TMT bar re-rolling mills. Types of Rolling Mills. The list of preferences for the hot rolling mill is the following.

Rolling Mill Guide Equipments Ispatguru

Prime Line Mill White Steel Guide Wheel 2 Pc Steel Bifold Doors Ace Hardware

What Are Roller Guide For Rolling Mill Kotobuki Sangyo Co Ltd

Guide To Stainless Steel Sheet Finishes Mill Polished Brushed Mirror

Rolling Mill And Its Technological Equipments Ispatguru

What Are Roller Guide For Rolling Mill Kotobuki Sangyo Co Ltd

Best Rolling Mill For Jewelry Making Buying Guide 2022 Craftbuds

Best Rolling Mill For Jewelry Making Buying Guide 2022 Craftbuds

0 comments

Post a Comment